JB/T 8219-2016 Ordinaria e intelligente attuatori elettrici industriali, sistemi di controllo di processo (standard nazionale per attuatori elettrici)

Standard nazionale per attuatori elettrici: JB/T 8219-2016 ordinaria e intelligente attuatori elettrici industriali, sistemi di controllo di processo (standard nazionale per attuatori elettrici)

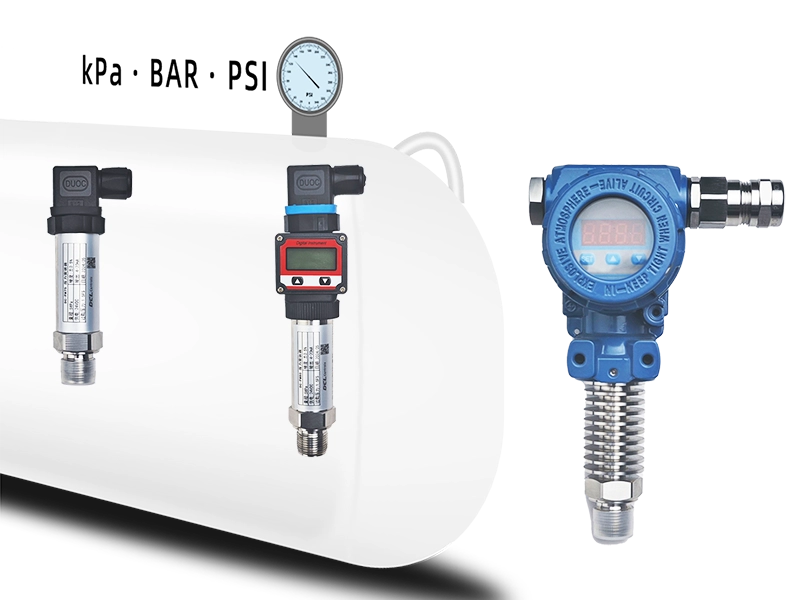

Attuatore elettrico tensione di segnale (1~5V, 0~5V,0~10V,-10V~10V) applicabile standard GB/T 3369.2-2008/IEC 60381-2:1978

电动执行器电压信号(1~5V,0~5V,0~10V,-10V~10V)适用标准: 过程控制系统用模拟信号 第2 […]

Attuatore elettrico segnale in corrente 4-20mA applicabile standard GB/T 3369.1—2008/IEC 60381-1:1982

电动执行器电流信号4-20mA适用标准: 过程控制系统用模拟信号 第 1 部分:直流电流信号(GB/T 336 […]

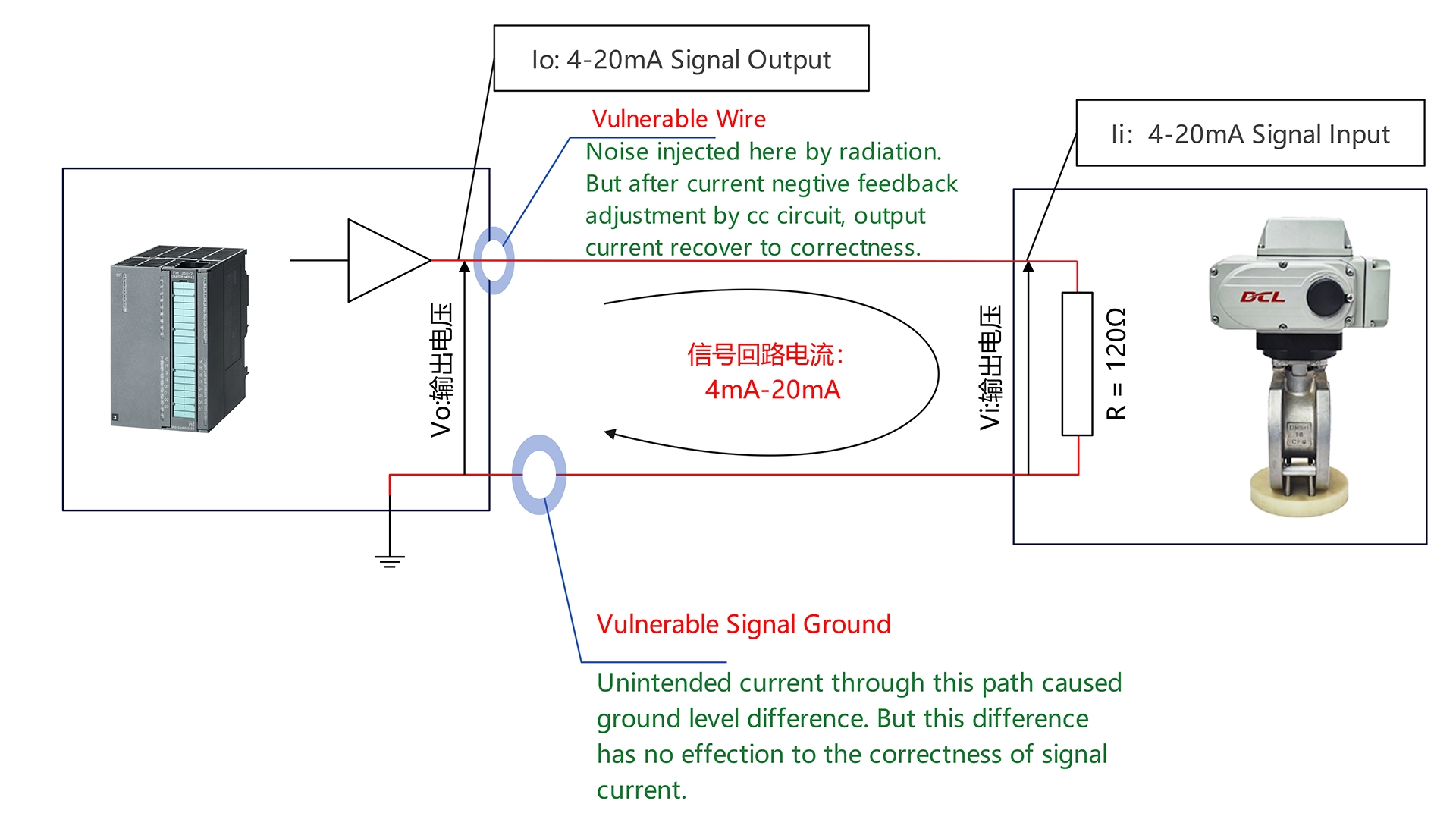

Grande concorso per la prestazione anti-interferenza di attuatori elettrici (4-20mA VS 2-10V)

在电动执行器抗干扰的应用中,使用4-20mA模拟信号比使用2-10V模拟信号的抗干扰性能好非常多,为什么?

Comune di autobus per attuatori elettrici

越来越多的工业控制系统开始部署现场总线,以实现更多的传感器和执行部件的控制。电动执行器做为流体控制 […]

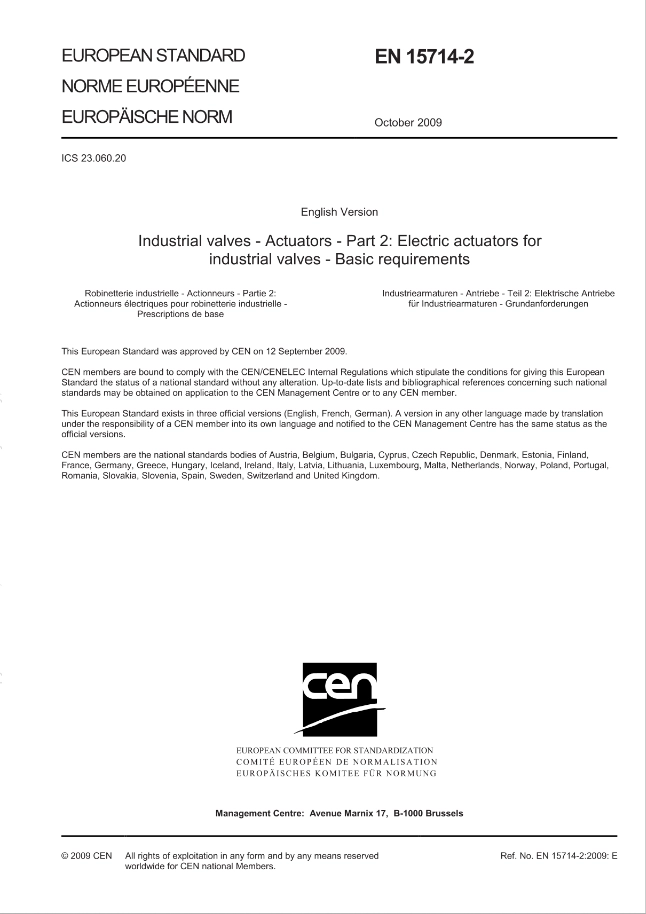

EN15714-2 classificazione delle attuatore elettrico modalità di controllo (dovere)

服务与支持 EN15714-2 对电动执行器控制方式(duty )的分类 EN15714-2 跟据 […]

In quali scenari avete bisogno di scegliere un processo di controllo dell'attuatore?

过程控制执行器的应用背景 在很多过程控制系统中,我们需要通过自动化控制系统(PLC/DCS)对液体 […]

Attuatore elettrico anti-interferenza di prova (EFT)

工业现场的电磁环境日趋恶劣 随着工业现场的电动化和智能化的不断提升,越来越多的大功率电气设备(千瓦 […]

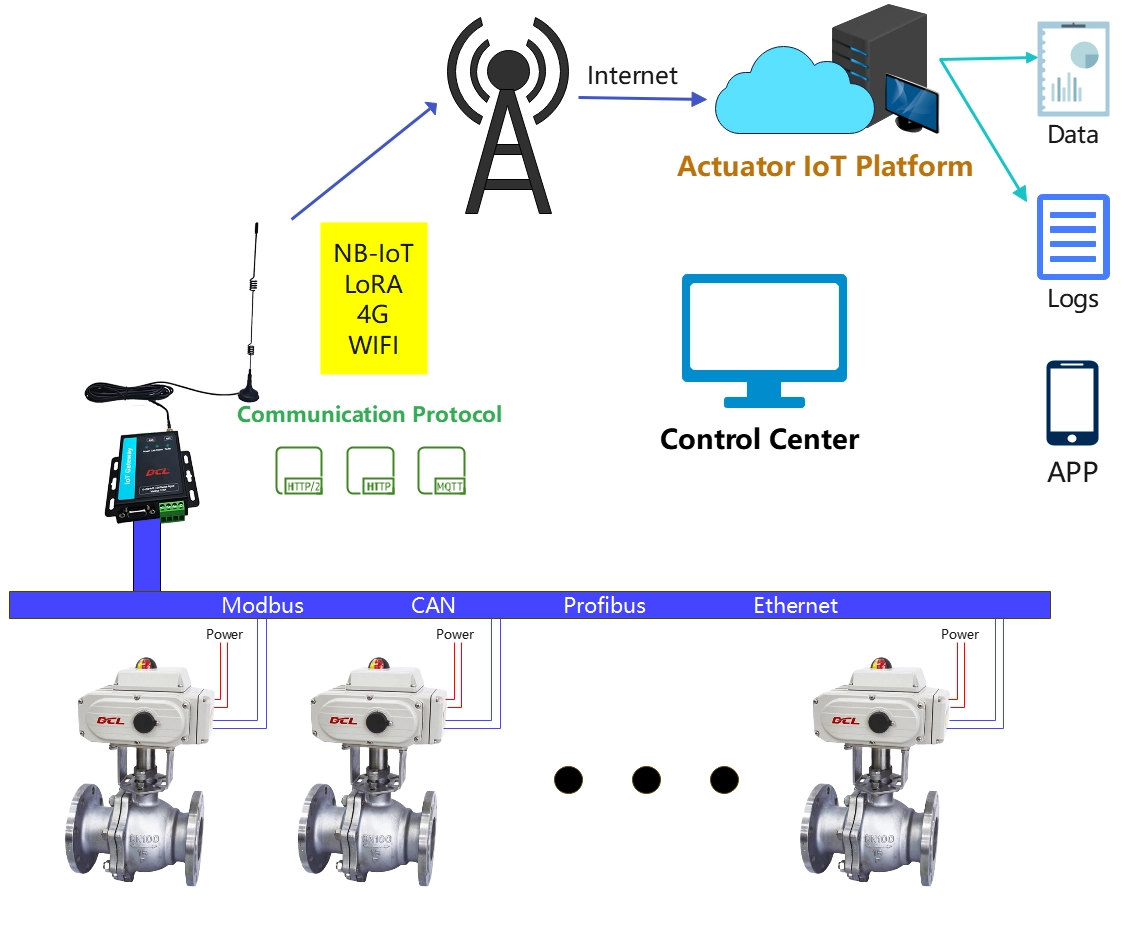

Il trend di sviluppo della digitalizzazione e messa in rete delle elettrovalvole

Rotork罗托克谈电动阀门数字化 Rotork最近在《欧洲控制工程》杂志上讨论了数字化对阀门自动化和控制的重 […]

Tipi e caratteristiche di comunemente utilizzati valvole

蝶阀 蝶阀使用一个圆盘来控制流体或气体的流动。圆盘安装在轴上,当手柄转动时,圆盘旋转90度,以允许或阻挡流体或 […]

Hubei Rete Pubblica Sicurezza N. 42018502006527

Hubei Rete Pubblica Sicurezza N. 42018502006527