이 마법사를 위해 적당 DCL 매우 작은 시리즈 액츄에이터 모델은 다음과 같습니다:

- DCL-02A/DCL-02B/DCL-02G

1. 일반적인 결함 및 문제 해결 방법이 있습니다.

| 결함 | 원인 | 제외 방법 |

|---|---|---|

| 액추에이터 전원이 켜지지 않습니다 또는 해제 할 때 그것은 처음 시작 | 1. 잘못된 배선 | 는지 여부를 확인 배선이 올바른 배선도에 따라 액추에이터의? |

| 2. 잘못된 전원 공급 장치 | 는지 확인하는 출력 전압 전원 공급 장치의±10%의 정격 전압의 액츄에이터,그리고 출력 전류는 3 배의 정격 전류의 액츄에이터입니다. | |

| 3. 비정상적인 제어 스위치 또는 통제 릴레이 | 멀티 미터를 사용하여 측정하는 입력 전압을 제어 터미널의 액츄에이터로 전환하는지 확인하 기대를 충족하는? | |

| 4. 제어 시스템을 일치시 문제 | 용 기계적 스위치를 측정하는 기능의 액츄에이터입니다. 는 경우 액추에이터가 정상적으로 실행되는지 여부를 확인 출력 논리 제어 시스템의 기대를 충족하는? | |

| 5. 여러 개의 액츄에이터 또는 액츄에이터와 병렬로 다른 장비 | 스위칭 액추에이터가 시작을 통해 시작 축전기,그리고 병렬로 연결된 다른 장비에 영향을 미칠 것이 커패시턴스 값을 시작하는 커패시터. 따라서,전환 액추에이터에 사용할 수 있는 단일 제어하지 않습니다. | |

| 액츄에이터를 설정할 수 있습니다 또는 off | 1. 잘못된 배선 | 1. 용 기계적 스위치를 측정하는 기능의 액츄에이터입니다. 는 경우 액추에이터가 정상적으로 실행되는지 여부를 확인 출력 논리 제어 시스템의 기대를 충족하는? 2. 는지 여부를 확인 배선이 올바른 배선도에 따라 액추에이터의? |

| 2. 부적절한 설정에 완전히/fullyoff cam | reference"어떻게 설정하는 스위치형 전기 벨브"설정,캠 위치습니다. | |

| 액추에이터 정의 중간에 여행 | 1. 밸브 침체 | 는지 여부를 확인 밸브가 붙어를 붙어있고,후 다시 시도하십시오 액추에이터에 의해 냉각 과부하 보호합니다. |

| 2. 잠재적인 고체에서의 유체 매체에 밸브가 정체. | 이 있는지 여부를 확인하는 고체에 갇혀있는 유동성 매체,제거 밸브 붙어있고,후 다시 시도하십시오 액추에이터에 의해 냉각 과부하 보호합니다. | |

| 3. 부적절한 설정에 완전히 완벽하게 off 스토퍼 | reference"어떻게 설정하는 스위치형 전기 벨브"설정,스토퍼 올바르게 배치. | |

| 손잡이를 사용하여,액추에이터의 회전 | 1. 잠재적인 고체에서의 유체 중간의 원인 밸브를 얻을 붙어 있습니다. | 이 있는지 여부를 확인하는 고체에 갇혀있는 유동성 매체,제거 밸브 붙어있고,후 다시 시도하십시오 액추에이터에 의해 냉각 과부하 보호합니다. |

| 2. 밸브 붙 | 는지 여부를 확인 밸브가 붙어를 붙어있고,후 다시 시도하십시오 액추에이터에 의해 냉각 과부하 보호합니다. | |

| 3. 액추에이터 감속 기구부가 손상되었습니다. | 제 액추에이터 밸브 및 핸들을 돌. 할 수 없는 경우 회전,그것을 대체하는 새로운 액추에이터입니다. | |

| 위치 피드백없이 신호 출력 | 1. 잘못된 스위치 결선 | 는지 여부를 확인 배선이 올바른 배선도에 따라 액추에이터의? |

| 2. 부적절한 설정에 완전히/fullyoff cam | reference"어떻게 설정하는 스위치형 전기 벨브"설정,캠 위치습니다. | |

| 3. 과전류에 손상을 일으키는 위치에 대한 피드백으로 신호를 전환합니다. | 1. reference"어떻게 설정하는 스위치형 전기 벨브"하는지 여부를 확인,완벽하게 on/fullyoff 캠 압축은 위치 피드백위치? 2. 은 측정 위치 피드백 루프를 켜? |

2. 는지 여부를 확인하시기 바랍 응용 프로그램 조건을 충족 매개변수 요구 사항입니다.

전기 액추에이터가 실패할 수 있습으로 인해 부적절한 사용 또는 잘못된 응용 프로그램 조건입니다. 응용 프로그램에 정의된 조건에서 제품의 명세,장기적인 문제없이 작동 액추에이터의 것되도록 보장하는 것이 필요합니다.

- 공급 전압:전압 전원 공급 장치의 내에 있어야 합니다 정격 작동 전압 범위의 액츄에이터입니다. 과전압 또는 저전압 발생할 수 있습 삶의 액츄에이터를 줄일 수 있습니다.

- 공급 전류:이후 시작하는 현재의 모터보다 훨씬 더 높이 평가 현재 있습니다. 을 지키는 신뢰할 수 있는 작업의 액츄에이터를 사용하시기 바랍 전원 공급 장치 출력 전류보다 더 큰 용량의 3 배의 정격 전류의 액츄에이터입니다.

- 온도:는지 확인 액추에이터 내에서 운영 정격 작동 온도 범위에서 사용할 수 있다. 사용 액추에이터의 환경에서는 초과하 정격 작동 온도 범위로 이어질 수 있는 가난한 액추에이터 기능 또는 감소 서비스,그리고 궁극적으로 실패로 이어질의 액츄에이터입니다.

- 환경:이 DCL 스위치형 액추에이터가 있 IP67 비바람에 견디는았습니다. 일반적으로 적합한 실내 또는 야외용됩니다. 제공하 어느 정도의 비와 스플래시 보호합니다. 보호 액추에이터에서 비,눈,얼음과 자외선(햇빛)일반적으로 수명을 연장합니다. 매우 부식성 환경에서 실행 중간에 오류가 발생할 수 있습 전자 장비입니다. 용도 외에 사용 하지 마십시오 폭발 방지 시리즈 액츄에이터에서 폭발 방지 환경입니다.

- Power-on continuity 평가:Power-on 연속성 비율의 DCL 전환 액추에이터 70%(실행 42 초당 분이 꺼져 있어야 합 18 초)입니다. 의 70%이상이 전력에서 연속성 비율의 원인이됩니다 모터를 입력 과열 보호합니다.

3. 는지 여부를 확인 배선의 액츄에이터가 올바른

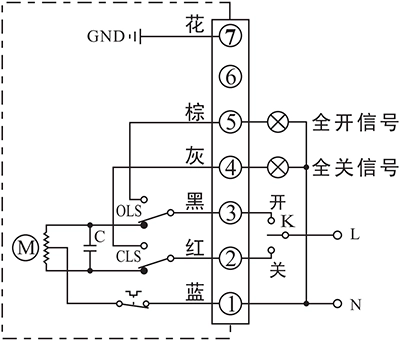

입력:제한 위치를 스위치(active 연락처)

"On"and"off"운영하는 것을 깨달았을 통해 스위칭 회로,그리고 집에 완전히고 완전히 활성 신호를 출력합니다.

배선 지침:

1. 1 터미널 연결되어 중앙선 전원 공급 장치의;

2. 전원 공급 장치 단계에라인 및 터미널 2 켜져 있으면 그것은"off"운영 있습니다.;

3. 전원 공급 장치 단계에라인 및 터미널 3 개가 켜져 있는,그것이"on"으로 작업이 있습니다.;

4. 전원 공급 장치와 제 2 터미널 연결되어 있고"off"작업이 장소에서"전체 신호"표시등을 연결하는 4 터미널에 있습니다.;

5. 전원 공급 장치 단계에라인 및 터미널 3 가 연결되어 있고"on"으로 작업이 장소에서"완전히 개방 신호"표시등을 연결하는 5 터미널에 있습니다.;

6. 터미널 7 접지 와이어입니다.

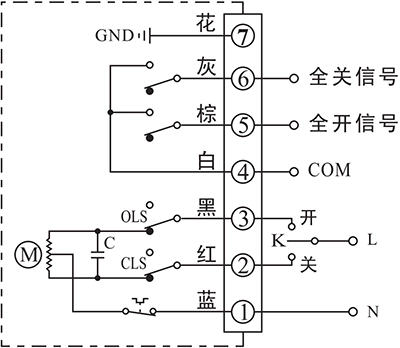

Type B:는 중간에 위치 스위치(수동적인 접촉)

"On"and"off"운영하는 것을 깨달았을 통해 스위칭 회로,그리고 집에 완전히고 완전히 오프 수동적 신호를 출력합니다.

배선 지침:

1. 1 터미널 연결되어 중앙선 전원 공급 장치의;

2. 전원 공급 장치 단계에라인 및 터미널 2 켜져 있으면 그것은"off"운영 있습니다.;

3. 전원 공급 장치 단계에라인 및 터미널 3 개가 켜져 있는,그것이"on"으로 작업이 있습니다.;

4. 4 터미널은 일반적인 터미널의 수동적 인 연락처니다;

5. 을 때"open"작업이 장소에서 5 터미널 출력에"완전히 개방 신호".;

6. 면"off"장소에서 터미널을 컴파일하고"전체 신호". 다;

7. 터미널 7 접지 와이어입니다.

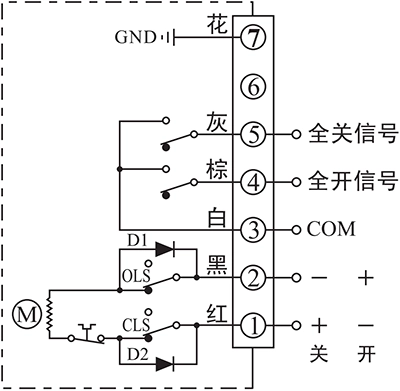

유형 G:직류 제어 회로를 가진 수동적인 접촉 스위치

에 따라 단방향의 전도성 다이오드,통해 긍정과 부정의 전극 DC 전원 공급 장치,"on"and"off"운영 실현되는 과정에 완전히고 완전히 오프 수동적 신호를 출력합니다.

배선 지침:

1. 1 터미널 연결하여 양극의 전원 공급 장치,그리고 제 2 터미널은"off"운영할 때에 연결되어 있는 부정적인 전극의 전원 공급 장치,제 2 터미널 연결하여 양극의 전원 공급 장치,그리고 제 1 터미널"에서"작업을 때에 연결되어 있는 부정적인 전극의 전원 공급이 있습니다.;

2. 3 터미널은 일반적인 터미널의 수동적 인 연락처니다;

3. 을 때"open"작업에서는 터미를 주지 않"완전히 개방 신호".;

4. 면"off"장소에서 5 터미널 출력에"전체 신호".;

5. 터미널 7 접지 와이어입니다.

를 수행할 때 조사는 프로젝트 현장에서 연락할 수 있습니다 우리 회사의 기술적인 서비스 직원으로 가능한 한 빨리 조사 결과를 확인 솔루션입니다.

연락처 번호:13026331611(첸 징)

Hubei 공용 네트워크 보안 No.42018502006527

Hubei 공용 네트워크 보안 No.42018502006527